Add to Cart

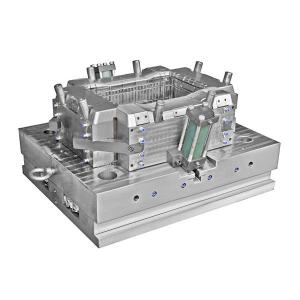

Automatic Small Plastic Products Custom Injection Mold For Sale

Quick detail Of Plastic Injection Mold

Product Material: plastic, ABS, PP, PC, PA, PMMA, PS, POM and etc.

Mould material: 45#,50#, P20, H13, 718 2738, NAK80, S136

Product name: Plastic Injection Mould, Plastic injection mold, Plastic Parts Injection Molding Service

Mould Base:FUT, ABA, LKM, HASCO, DME

: cold / hot

Tolerance: 0.02mm -0.05mm

Certification: ISO 9001:2008,ISO9001-2015, CE

Cavity:Single or Multy

Mould Life: 250000-300000shots

Service: OEM Services Provided, Customized logo

Color: Black, Various colors

Surface finishing: Laser Machining/ Screen Printing / Drilling/Chemical Ecthing / Polishing / Mirror Finishing/UV Printing/Electroplate

1, Start from part design analysis.

2, Mold design drawing and DFM report available so you can see how is the mold going to be before mold making.

3, If product is complex, moldflow report will be present as well.

4, In house mold making shop ensure you mold quality under well control.

5, Normally it takes 20-40 days to make mold, precise time depends on part design.

Application Of Plastic Injection Mold

Use for machinery

Use for electronic

Use for automotive

Use for information technology industry

Use for Space industry

Use for Medical industry

Use for Energy industry